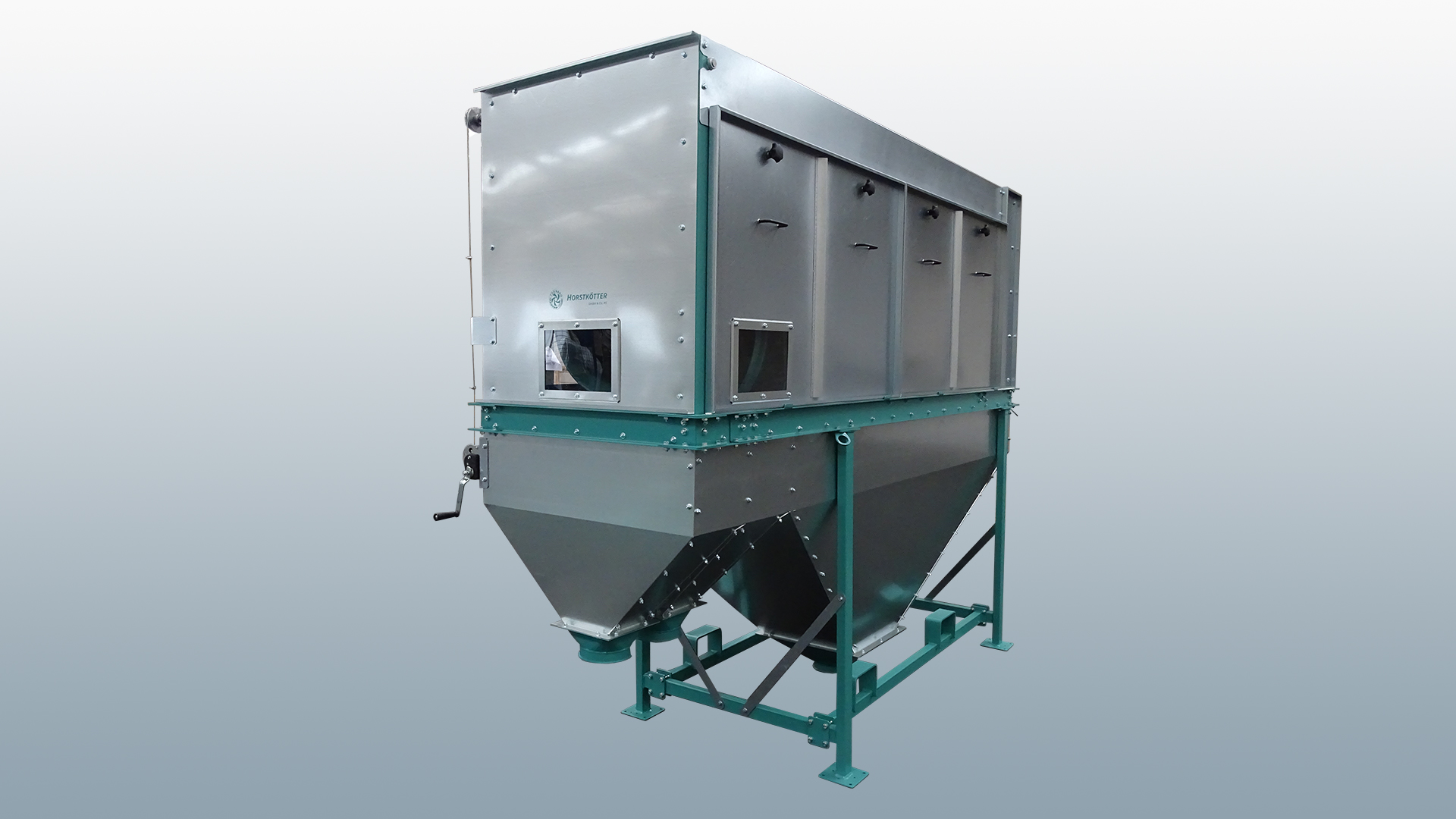

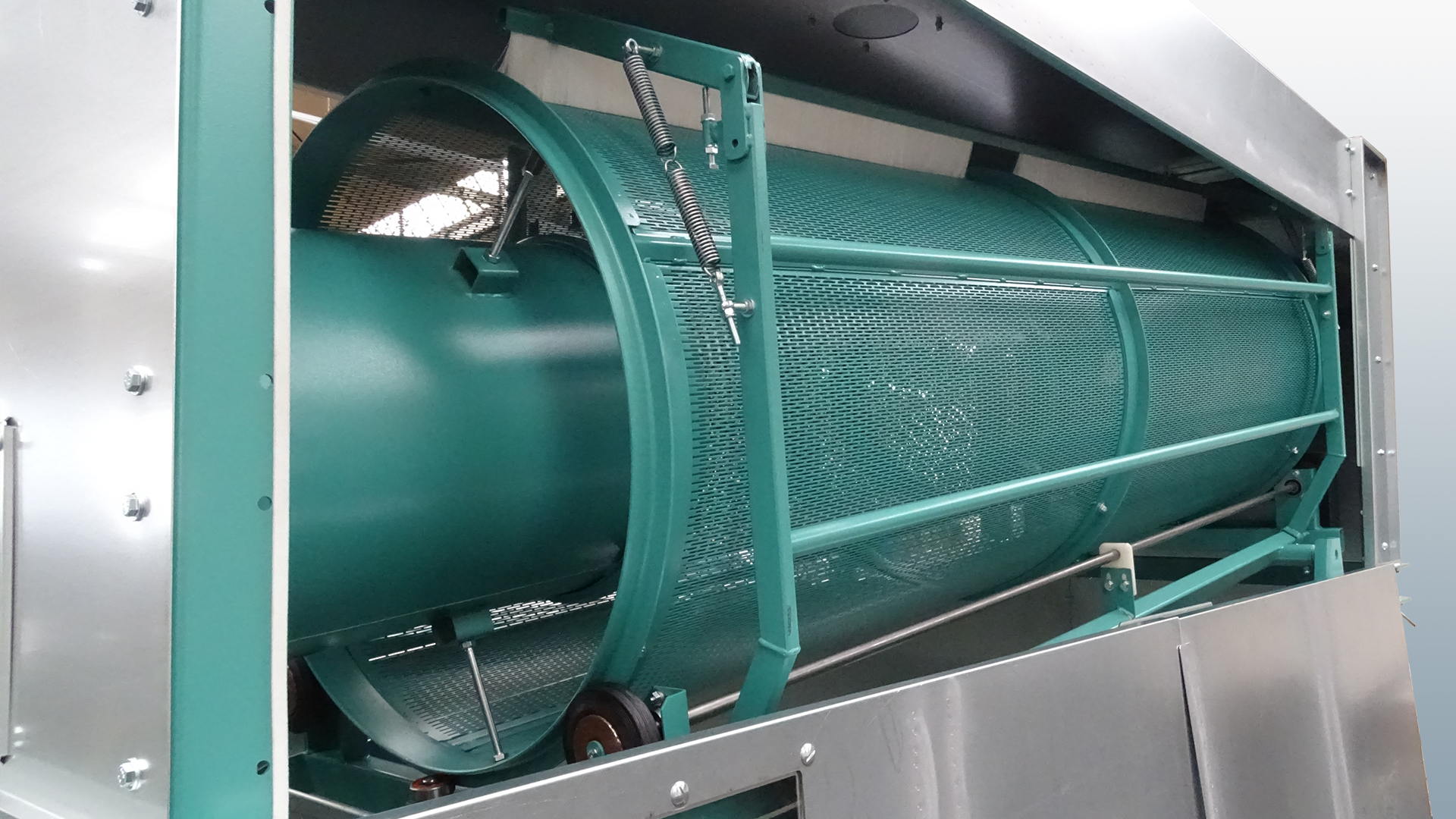

Cleaning with a drum cleaner is suitable for separating bulk materials of different sizes or shapes. The material flows over a rotating sieve in the drum cleaner and is separated into two fractions. The cleaning performance is initially influenced by the sieve used. Both the type of sieve (slotted hole, round hole) and the diameter of the perforation must be adapted to the bulk material. In addition, the inclination of the sieve determines the throughput and the cleaning result.

Our drum cleaners are mainly used in agriculture and are particularly suitable for organic farming. In addition to the standard version, we also produce drum cleaners with internal sieve for separating grain into three fractions. For higher capacities (up to 80 t/h) we also offer a double drum cleaner with two parallel sieves. We produce a wide range of different slotted and round sieves, so that the drum cleaner can be used in many areas. The sieve segments are interchangeable and easy to install. The TTR works energy-saving and with no vibration, so that it can also be installed on intermediate floors.

Round hole sieve: cleaning out coarse parts (thistle heads, straws, corn spindles)

Slotted sieve: cleaning out small particles and fine impurities (sand)

Inner and outer sieve: cleaning of coarse and fine impurities in one operation, e.g. for cleaning the rape seed before a rape press

Type |

|---|

TTR 630 |

TTR 630-I |

TTR 800 |

TTR 800-I |

TTR 800D |

TTR 800D-I |

Round hole Ø12 mm | Oblong hole Ø3 x 25 mm | With inner sieve |

|---|---|---|

20 t/h | 2 – 3 t/h | – |

20 t/h | 2 – 3 t/h | 2 – 3 t/h |

40 t/h | 7 – 9 t/h | – |

40 t/h | 7 – 9 t/h | 7 – 9 t/h |

80 t/h | 14 – 18 t/h | – |

80 t/h | 14 – 18 t/h | 14 – 18 t/h |

Type |

|---|

TTR 630 |

TTR 630-I |

TTR 800 |

TTR 800-I |

TTR 800D |

TTR 800D-I |

Round hole Ø12 mm | Oblong hole Ø3 x 25 mm |

|---|---|

20 t/h | 2 – 3 t/h |

20 t/h | 2 – 3 t/h |

40 t/h | 7 – 9 t/h |

40 t/h | 7 – 9 t/h |

80 t/h | 14 – 18 t/h |

80 t/h | 14 – 18 t/h |

Typ |

|---|

TTR 630 |

TTR 630-I |

TTR 800 |

TTR 800-I |

TTR 800D |

TTR 800D-I |

Combination with inner sieve |

|---|

– |

2 – 3 t/h |

– |

7 – 9 t/h |

– |

14 – 18 t/h |

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Mapbox. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from OpenStreetMap. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information