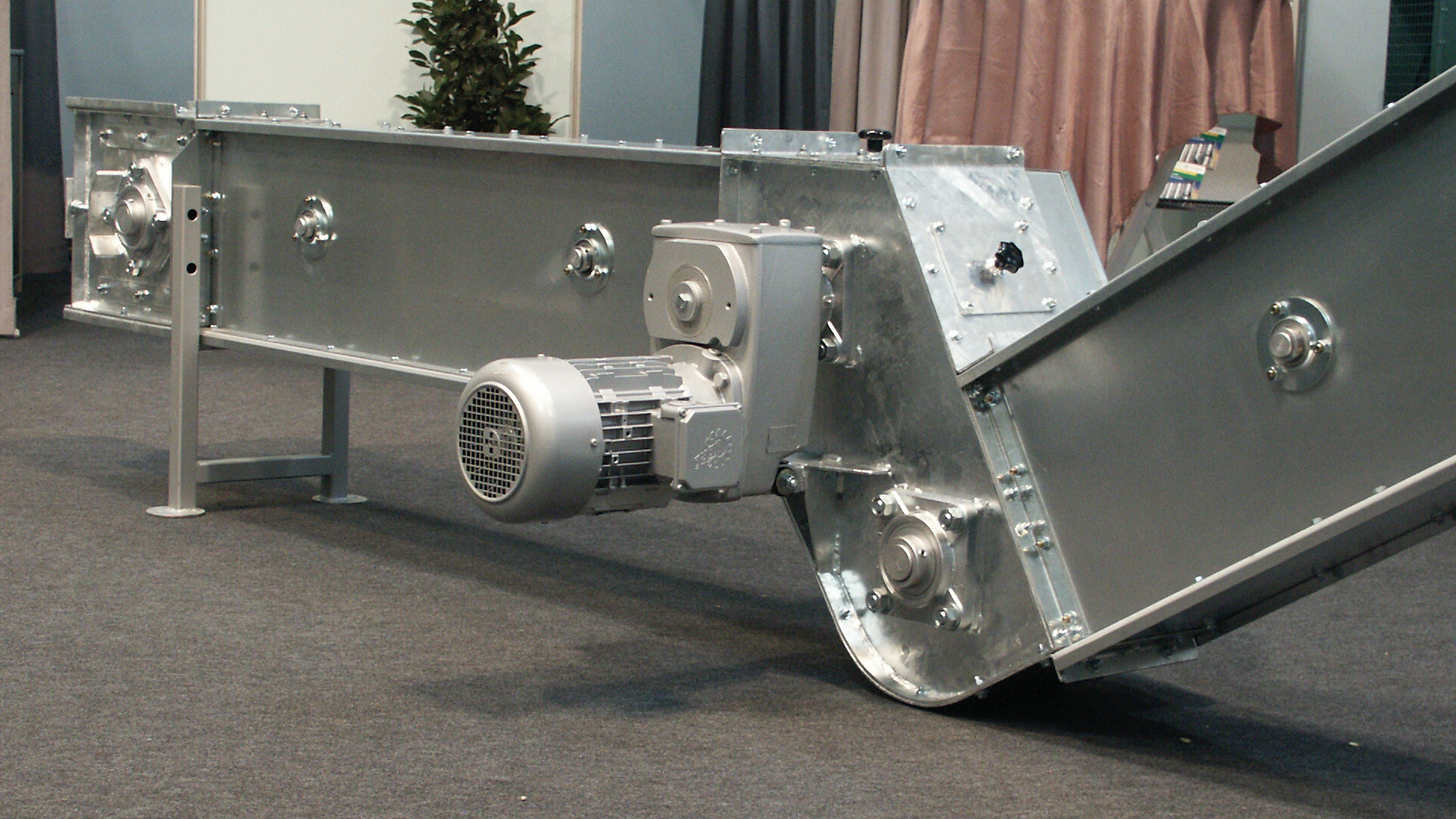

Trough chain conveyors are suitable for the horizontal transport of bulk materials up to a maximum gradient of 20°. Due to their stable design and their high conveying capacity of up to 200 t/h (bulk density 0.75 t/m³) they can be used in the agricultural as well as in the industrial sector. Typical applications are, for example, receiving pits, silo filling and silo emptying. For receiving pits, the chain conveyor is equipped with special receiving troughs. The bulk material should be free-flowing, dry, non-abrasive with a grain size of 0 – 20 mm. Other bulk materials can also be conveyed after individual, technical clarification.

We supply trough chain conveyors with conveying capacities of 25 – 200 t/h. In addition to the horizontal conveying of bulk materials, our trough chain conveyors can also be used as lifting conveyors. In this case an additional 30° drive station is used, so that the material can be lifted directly to another conveyor. This eliminates the need for an expensive pit. All trough chain conveyors are equipped with conveyor discs made of plastic or fabric belt for low-wear and product-friendly conveying. In addition, safety devices such as bulwark detectors and speed monitoring can be integrated into the conveyor technology.

– |

|---|

Trough in mm |

Capacity in m3/h |

TTF 25 | TTF 40/60 | TTF 80/100 |

|---|---|---|

194 X 344 | 265 X 470 | 424 X 456 |

33 | 53 – 80 | 106 – 133 |

– |

|---|

Trough in mm |

Capacity in m3/h |

TTF 120/150 | TTF 200 |

|---|---|

550 X 456 | 550 X 555 |

160 – 200 | 265 |

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Mapbox. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from OpenStreetMap. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information