You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

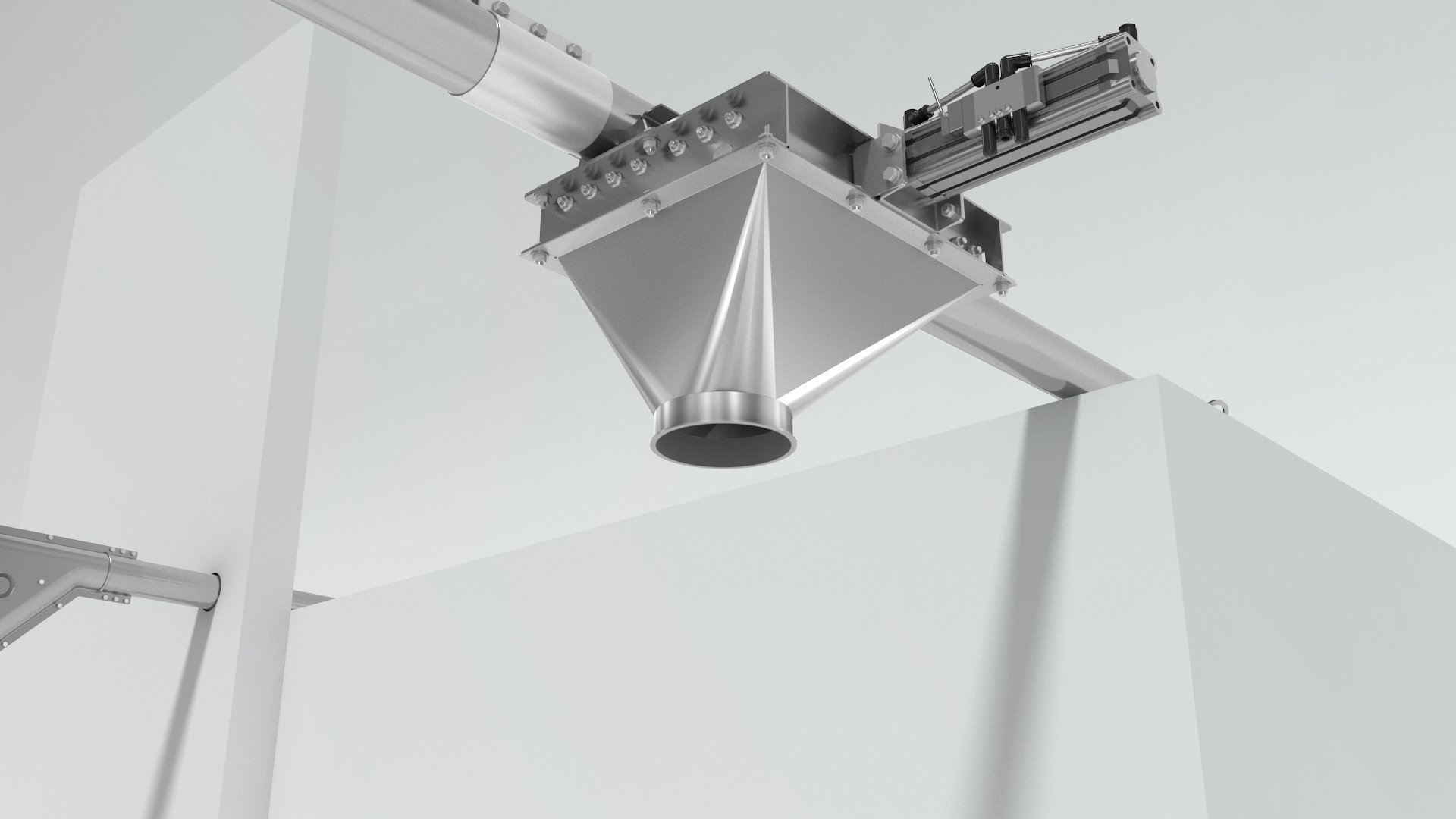

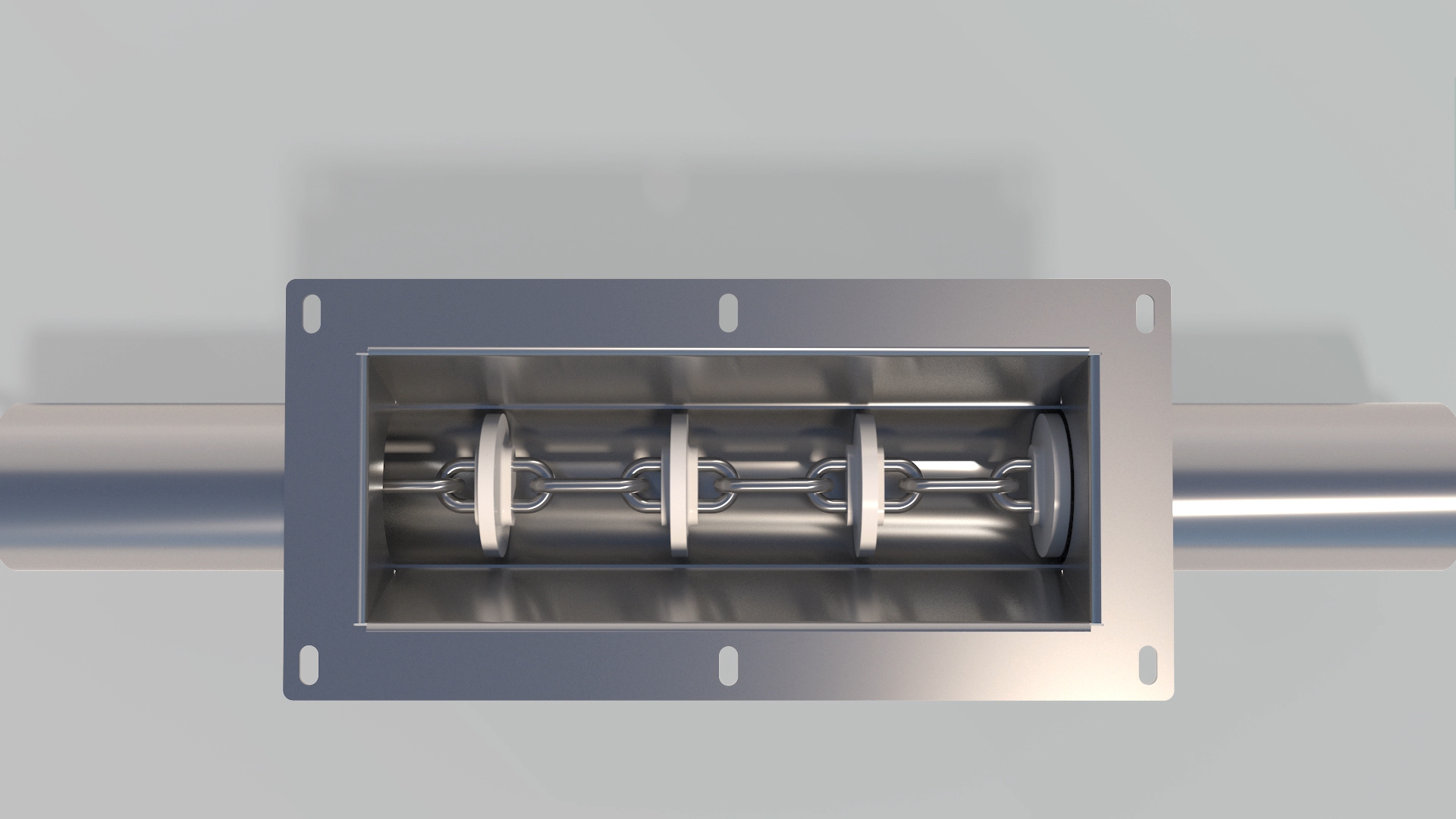

More InformationTubular chain conveyors are the ideal equipment when dry, free-flowing bulk materials have to be conveyed in small spaces and with complex conveying paths. By using return stations and deflection bends, any three-dimensional line layout is possible, so that further plant components in the room can be reached easily. Due to this flexibility, tubular chain conveyors are already successfully used in plastics processing, breweries, the food industry, feed processing and various other industries. New applications are continuously adding to this list. In general, both powdery and granular products up to a grain diameter of 20 mm can be transported. In many cases, the tubular chain conveyor offers the possibility to reduce operating costs by replacing several individual conveyors.

We supply tube chain conveyors in four different sizes with conveying capacities from 2.2 to 34.0 t/h (bulk density 0.75 t/m³). The conveyor is designed specifically for each application and the line layout including all inlets and outlets is closely coordinated with the customer. For continuous industrial operation with abrasive products robust iron cast stations are used, whereas stainless steel versions are often used in the food industry. The material of the conveyer discs depends on the material to be conveyed and the environmental conditions. Additional safety devices such as speed and chain breakage monitoring as well as an automatic chain tensioning device can be easily integrated into the system. Our tube chain conveyor is suitable for use in ATEX zones 21/22.

– |

|---|

Outer diameter in mm |

Flow rate in m3/h |

TRK 60 | TRK 90 | TRK 115 | TRK 160 |

|---|---|---|---|

60 | 90 | 115 | 160 |

2.9 | 8.0 | 16.0 | 46.0 |

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Mapbox. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from OpenStreetMap. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information